Standard 6 x 19 and 6 x 36 Classification Ropes

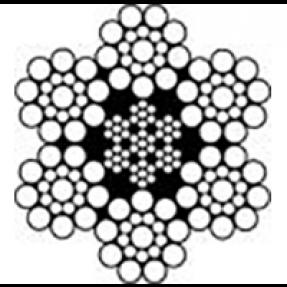

The 6 x 19 classification of wire ropes includes standard six strands, round strand ropes with 16 through 26 wires per strand. The 6 x 36 classification of wire ropes includes standard six strands, round strand ropes with 27 through 49 wires per strand. Although their operating characteristics vary, all have the same weight per foot and the corresponding minimum breaking force, size for size.

While the 6 x 19 ropes give primary emphasis to abrasion resistance in varying degrees, the 6 x 36 cables are essential for their fatigue resistance. This fatigue resistance is made possible by the higher number of small wires per strand.

Although there are exceptions for specialized applications, the constructions in 6 x 36 classification are primarily designed to be the most efficient for each rope diameter. As the rope size increases, for instance, a large number of wires can be used to achieve required fatigue resistance, and still those wires will be large enough to offer adequate resistance to abrasion.

Characteristics Of Standard 6 x 19 And 6 x 36 Wire Ropes

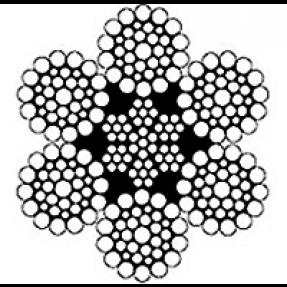

- 6 x 19S (SEALE) This is a good rope to withstand abrasion or crushing on the drum, with decreased fatigue resistance.

- 6 x 25FW (FILLER WIRE) To most wire rope users, 6 x 19 means 6 x 25 filler wire. It is a common rope in the 6 x 19 classification.

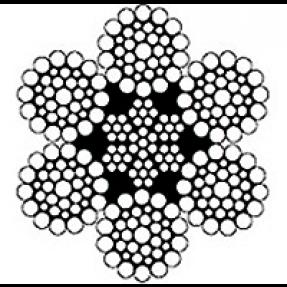

- 6 X 26WS (WARRINGTON SEALE) A standard

- 6 x 26WS design provides the best rope for a wide range of applications.

- In general, we recommend the use of a 6 x 26WS in any application using 6 x 25FW.

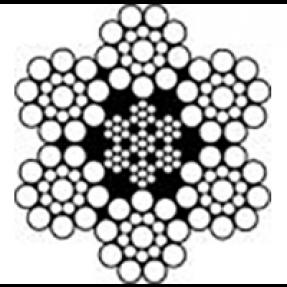

- 6 x 36 CLASS ROPES

In most rope sizes, only one 6 x 36 classification rope is made. These constructions were selected to provide fatigue resistance without having wires that are too small.

The higher number of wires in the 6 x 36 classification makes these ropes more susceptible to crushing. Crushing can be minimized, however, by specifying an Independent Wire Rope Core (IWRC) and by using well-designed sheaves, grooved drums, and proper operating techniques.