All wire ropes will wear out eventually and gradually lose work capability throughout their service life. That's why periodic inspections are critical. Applicable industry standards such as ASME B30.2 for overhead and gantry cranes or federal regulations such as OSHA refer to specific inspection criteria for varied applications.

Perform regular inspection of wire rope and equipment for three good reasons:

- It reveals the rope's condition and indicates the need for replacement.

- It can indicate if you're using the most suitable type of rope.

- It makes possible the discovery and correction of faults in equipment or operation that can cause costly accelerated rope wear.

You should thoroughly inspect all wire ropes at regular intervals. The longer it has been in service or, the more severe the service, the more thoroughly and frequently it should be inspected. Be sure to maintain records of each inspection.

Inspections should be carried out by a person who has learned through specialized training or practical experience of what to look for and who knows how to judge the importance of any abnormal conditions they may discover. It is the inspector's responsibility to obtain and follow the proper inspection criteria for each application inspected.

What to Look For

Figure 1 is what happens when a wire breaks under tensile load exceeding its strength. It's typically recognized by the "cup and cone" appearance at the point of failure. The necking down of the wire at the point of failure to form the cup and cone indicates failure has occurred while the wire retained its ductility (the ability to change form without breaking).

Figure 2 is a wire with a clear fatigue break. It is identified by the square end perpendicular to the wire. This break was produced by a torsion machine that's used to measure the ductility. This break is similar to wire failures in the field caused by fatigue.

Figure 3 is a wire rope that has been subjected to repeated bending over sheaves under typical loads. This fatigue results in breaks in individual wires - these breaks are square and usually in the crown of the strands.

Figure 4 is an example of fatigue failure of a wire rope subjected to heavy loads over small sheaves. The breaks in the valleys of the strands are caused by "strand nicking." There may be crown breaks, too.

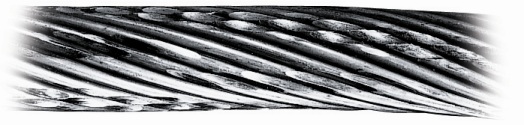

Figure 5 is a single strand removed from a wire rope subjected to "strand nicking." This condition is a result of adjacent strands rubbing against one another. While this is normal in a rope's operation, the nicking can be accentuated by high loads, small sheaves or loss of core support. The ultimate result will be individual wire breaks in the valleys of the strands.